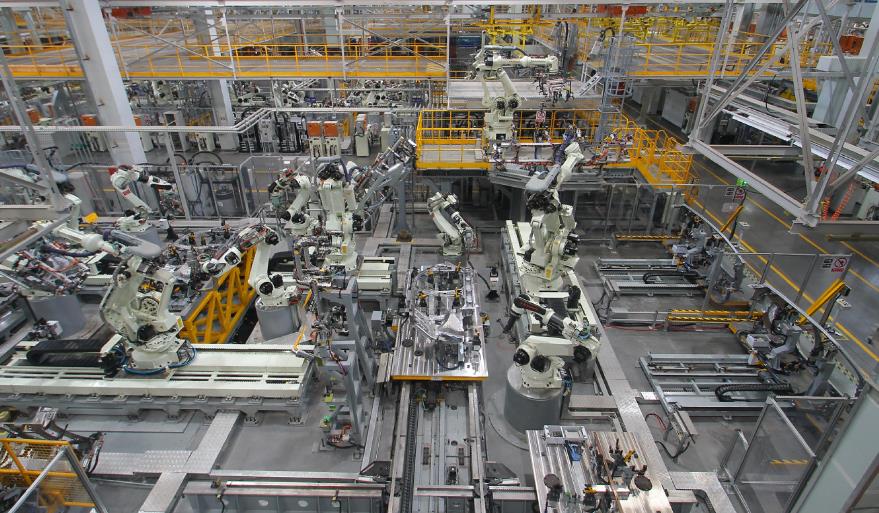

Flexible Production Line with High Production Capacity

The line speed of the production line is 60JPH; 4 models are mixed in a line; 260 units of robots are in operation; the production capacity and automation rate are the highest level of independent brands, reaching the standard of mainstream joint venture brands.

The main welding line is equipped with high-speed hemming machine, which takes up only 10 seconds to convey, leaving more time for welding operation.

High-speed flexible fixture switching system ensures fast mixed-flow production for 4 models.

Large-scale logistics is basically above the air platform to ensure smooth ground logistics.

Application of new technologies, new processes and new materials

Lightweight welding torch technology, intermediate frequency AC/DC welding technology, welding parameters network monitoring technology;

Automatic detection technology of glue coating;

Visual guidance technology;

On-line measurement technology of body accuracy;

Auto-hemming, engraving, gluing, stud welding, CMT welding technology

Perfect equipment monitoring, energy monitoring, AVI system, and ANDON system ensure that the production line is safe, reliable, energy-saving, and environmental protection;

Digital virtual technology is applied to Changan flexible welding line for the first time, which shortens the project development cycle, reduces project risk and facilitates the introduction of new products later.