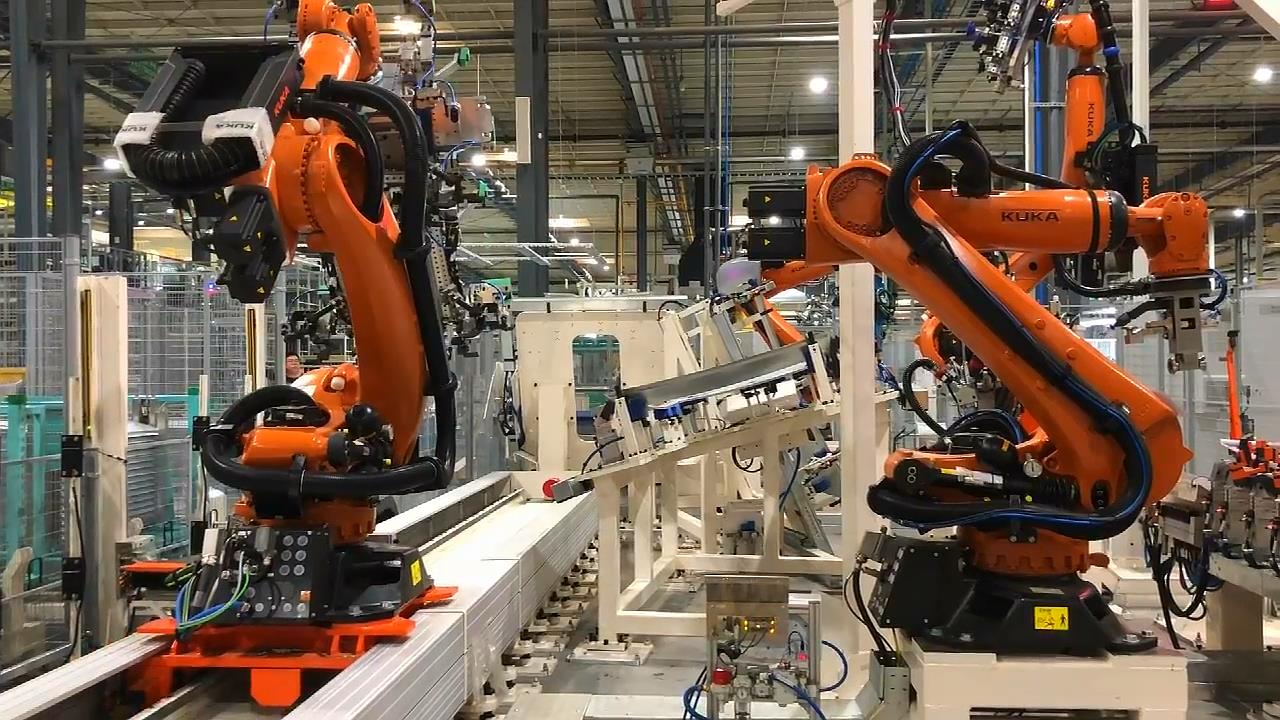

CT: 157S (19U)

Main Nodes: Delivery in December 2016 and mass production in March 2018.

Project scope: Front Floor Line, Hood Line, Fender Line

Project features: high-end car parts project, aluminum bodyclinching technology, high automation rate

Process application: Medium Frequency Spot Welding (floor Line), Projection welding,Screw & Nut Clinch, Aluminum Body Clinch (No nail riveting), Robot hemming (Aluminum Body), Robot Gluing & Visual Detection

Coverage:

Front Floor Line:50m*20m

Hood Line:23m*15m

Fender Line:13m*12.5m

Robot Integration: 34 units (fanuc)

Automation rate: 95%, manual loading; the rest are completed by robots (spot welding,clinching, gluing, hemming, handling)